Weeping Walls

Offering a solution to farmers on effluent screening , RX Plastics has developed a weeping wall using a triangular shaped profile of PVC. Traditionally weeping walls have been made from timber, which has a disadvantage of swelling under wet conditions and shrinking under dry conditions . This causes the spacings in a weeping wall to be inconsistent in turn allowing solids to pass through the screen. The introduction of the PVC effluent bar as a medium has provided a product that does not break down over time, does not swell or shrink and provides a consistent gap for solids removal.

The design of differing gaps between profiles and various sized panels makes this an ideal solution to a variety of pond styles and effluent types. The triangular bar gives a higher physical strength to the wall and the shape allows efficient liquid flow while holding back solids.

FEATURES

- Made of PVC with high physical strength

- High UV stability

- Non-corroding - won’t rust

- Will not swell or warp

- Will not rot

- Smooth surfaces

- Triangular bar shape, provides more flow and self cleaningBenefits

BENEFITS

Separates valubale effluent into components taht are more easily managed and distributed

Triangular bar gives maximum strength and no barrier to effluent liquid flow while holding back solids

Made from an effiecient bar extrusion that allows various gap spacing between bars (standard spacings are; 4mm, 6mm and 8mm)

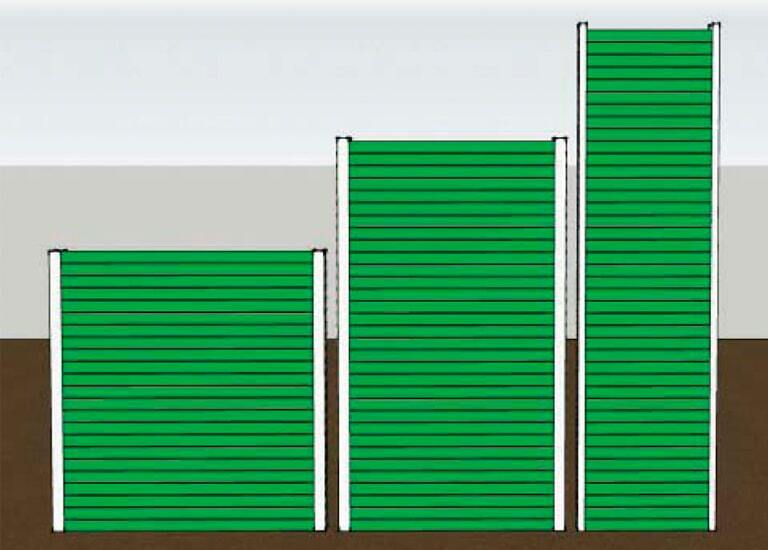

We have a range of sizes available (standard sizes are are; 1210mm wide x 1200mm high, 1000mm wide x 1500mm high and 610mm wide x 2000mm high), please refer to your consultant for advice on what size pnels would best suit your requiremenst

RESULTS

Grenn water with minimal suspended solids

SELECTING GAP SIZE

4mm Gap

- Hosing straight off a yard or flood wash

- Low fibrous material

- Relatively high water content

6mm Gap

- Hosing straight off a yard or flood wash

- Average / normal fibrous material

- Average / normal water content

8mm Gap

- For use inn feed lots where the yards are scaped to clean

- High fibrous material

- Relatively low water content

How many panels do you need?

Rule of thumb is 1 panel per 100 cows would be needed per drying bed